Enhancing customer flexibility through

industrial intelligence and operational excellence

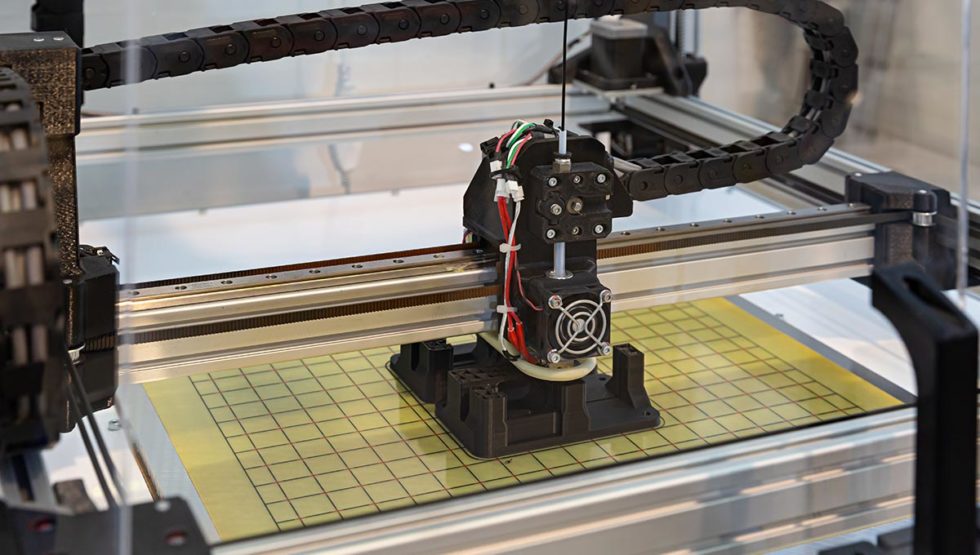

Smart Manufacturing

arpa smart manufacturing tool is dedicated to the production of radiant ceramic cooktops, induction hobs, built-in appliances, extractor hobs, cooker hoods, ovens and connected kitchen appliances.

arpa relies on a smart manufacturing tool capable of simultaneously providing several production models: from mass production to on-demand or customized small runs while preserving the productivity and profitability of operations.

This ultimate flexibility relies on a unique manufacturing model based on 2 entirely autonomous plants:

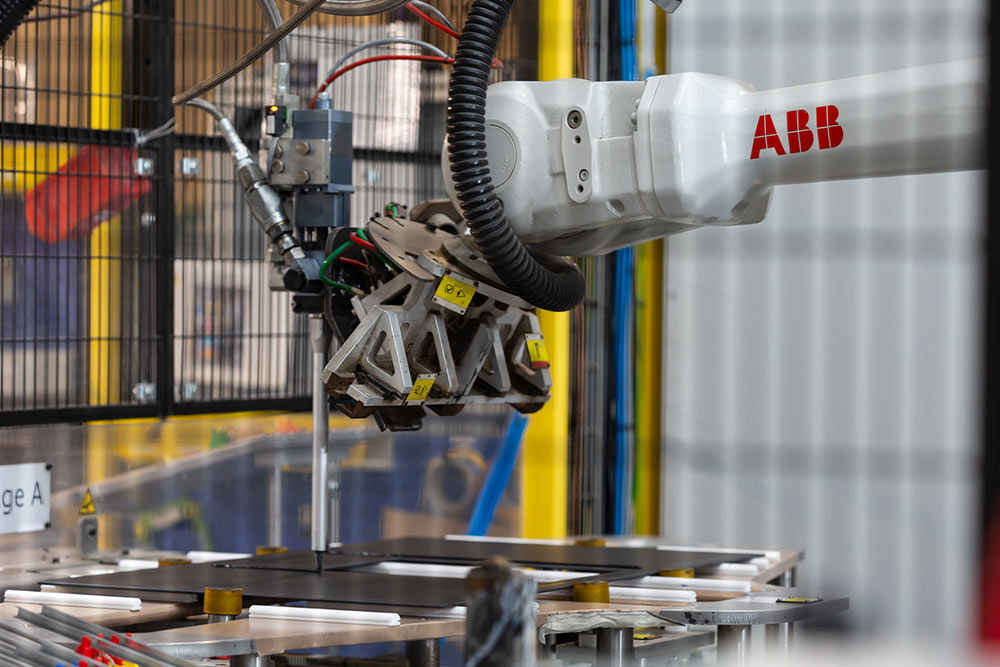

High Runner Factory for mass production

Current capacity of 700’000 cooktops a year Production batches ranging from 100 to 5000 units

High Mix Factory for on-demand or customized production

Minimum Order Quantity of as little as 1 pallet

More than 200 new projects every year

Both factories are at the state-of-the-art of large kitchen

appliances manufacturing; mastering assembly, pre-assembly and

bonding expertise.

arpa’s industrial intelligence enables us to modulate our

production tool in order to address any new kitchen appliance

development in less than 3 months:

specifying project

designing synchronised flow manufacturing

2D and 3D mock-ups

co-constructing equipment with Arpa production teams

assessing POC

adjusting and implementing

Bulk-Buying Capability

More than 200 customer brands rely on arpa’s expertise worldwide to provide them with 100% customized kitchen appliances. This strengthens arpa through significant bulk-buying capability and shapes its competitiveness – and so that of its customers – on the market.

Just-In-Time Delivery

Kitchen appliances customization is boundless. To address efficiently customers’ tailor-made expectations, arpa must outpace competitors with an extremely agile supply chain. Its lean management approach and streamlined production processes enable arpa to out-perform in Just-In-Time delivery.